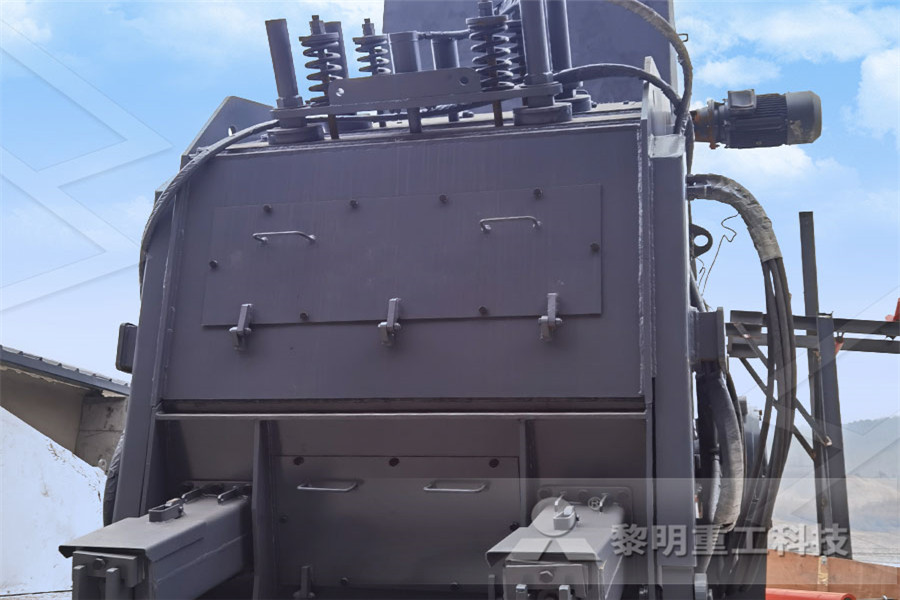

philippines mining processing plant system components

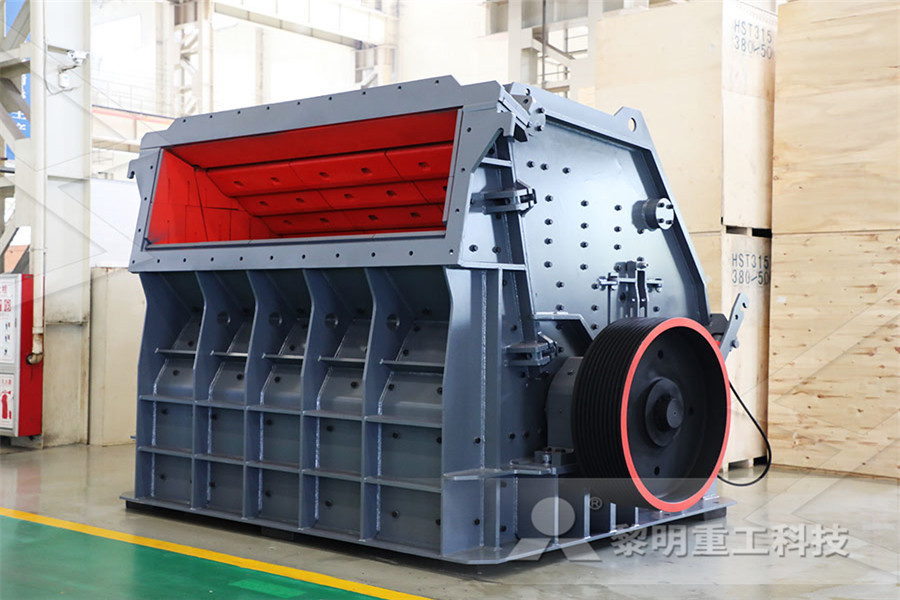

philippines mining processing plant system components Apex Mining Co Inc the Company was incorporated and registered with the Philippine Securities and Exchange Commission on February 26 1970 primarily to carry on the business of mining milling concentrating converting smelting treating preparing for market manufacturing buying selling exchanging and otherwise producing and dealing in components of crushing plant components of crushing plant Mining crushers mainly include jaw crusher, cone crusher, impact crusher, mobile crusher for crushing stone, rock, quarry materials in mining industrymain components of the aggregate crushing plant Gold Ore Crusher Read moreMain Components Of The Aggregate Crushing Plantcomponents of a coal processing plant Mining Home Once mined, the coal is transported to the Coal Handling and Preparation Plant where the minor waste component, usually clay or sandstone, is washed away Read morecomponents of a coal processing plant General processing technologies for gold ore are summarized as below: I Physical Gold processing technology: CrushingGrinding Gravity Separation Flotation Process Agglomeration II Chemical Gold processing technology: Carbon in Leaching (CIL) Carbon in Pulp (CIP) Heap Leaching (Dump leaching) Desorption Electrolysis Process Smelting Refining ProcessingGold Processing Plant Prominer (Shanghai) Mining Main components of a Resources Backfill Plant include: PUG Mill Medium Feeder Weightometer Flow Meter and Control Valve Specialized Backfill Pumps Thickened Slurry Holding Tank Slurry Pumps Backfill plants utilize a medium such as Mining Backfill Plant Resources Gold Technology

ABB in Mining

ABB in Mining ABB in Mining delivers complete plant electrification, integrated process control and optimization solutions, motors and drives systems as well as instrumentation and analyzer systems Home Offerings ABB in Mining For mineral processing project, after blasting, crushing and screening system is always the first stage to reduce the big raw ore lumps to proper small particle size for following mill grinding system Normally to reduce the big ore lumps to small particles, CrushingScreening System For Mineral Processing Buy Components From 3,0005,000 Tpd Plant Including 3,000 Hp Fls Ball Mill, 3,000 Hp Sag Mill, Slon Outotec Magnetic Separators, Pumps And Much More! from AM King Industries Request a quote online ponents From 3,0005,000 Tpd Plant Including There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of partiesCrushing Plant Design and Layout Considerations Metallurgical processing of metalliferous ores in general and gold ores in particular, consists essentially of three stages, often colloquially referred to as: Bashing (crushing); Mashing (grinding); and; Hashing (extraction/recovery) In the context of flowsheet selection, the bashing and mashing Gold processing 101 Mining Magazine

Mining Belterra

Steep Incline Conveyors in Mine Processing Plant Belterra installed all the conveyor belts in this mines’ processing plant including the 4 HAC (high angle system) systems These vertical conveyors are specially designed for steep inclines requiring a minimal amount of space This system employs standard troughed belt components in a simple Mining Systems and Equipment TAKRAF is recognized as one of the world's leading technology brands providing specialized mining systems and equipmentOwners and operators around the world trust our engineered solutions that leverage our experience acquired over more than a century Our portfolio ranges from excavating to primary crushing stations, IPCC systems, inpit and underground conveying Mining Systems Equipment TAKRAF GmbHWe leverage our datacentric approach to engineer safe, reliable, and costeffective mineral processing facilities that are optimized to overcome operational challenges Tailings are a fundamental byproduct of mining processes Their management is an essential component of the design, development, and operation of mining facilitiesMineral Processing Plant Design Engineering Services Optimizing mining operations 43 mining and as a provider of all of these system components within a single suite, the company is able to derive the KPIs required to support optimal organizational performance Once the right KPIs are determined Ventyx has Optimizing mining operations ABB NQ Minerals says it has successfully increased plant throughput at its flagship Hellyer gold mine, in Tasmania, Australia, following an upgrade and circuit optimisation exercise The plant now has a capacity just over 13 Mt/y (12 Mt/y at 92% plant availability), up from the 835,877 t throughput level achieved in 2019, NQ saidNQ Minerals upgrades Hellyer processing plant, aims

Partner to the Mining Industry

Maximum system availability is therefore an absolute must for mining and processing energy minerals Unexpected downtime, which causes high costs and losses, must be kept to a minimum This can be achieved with automation technology and components with diagnostic capabilities devices It transmits this data to the controllers via fieldbus System solutions Cement and mining industry The cement and mining industry is under enormous pressure these days to innovate In particular, the burgeoning importance of efficientenergy production plants and environmentally friendly processes constantly call for new developmentsSystem solutions Cement and mining industry VEM Inplant conveyor systems are utilized within the mining, minerals processing, paper pulp and power generation industries to receive/unload, stockpile, reclaim and deliver various material types within a plant Inplant conveyor system for a mine mouth coal fired power plant in USA Services Components Expertise Conveying TAKRAF GmbH Mineral Processing LEARN MORE > Conveyors LEARN MORE > Stacker/Reclaimers LEARN MORE >Rockwell – RockwellTailings water treatment for mining and mineral processing operation often involves the handling of water with significant amounts of abrasive suspended solids Pumps for drywell installations are available with highly wearresistant hydraulic components that help ensure longer service lives and reduce maintenance requirements under arduous Pumps for the mining and processing industries

Diamond Processing Plants Mining Technology

Customisation – a tailored turnkey processing system is built according to the feed material used, to match the final product specifications and capacity requirements Modularity – CDE’s systems are designed as modular components or individual building blocks to ensure a synergy between all individual pieces of equipmentMining and mineral processing industries Solutions from mine to market (English pdf Brochure) Drives system solution ACS880 for Openpit Mining (English pdf Brochure) Automation solutions and electrical equipment for openpit mining and bulk handling (English pdf Brochure) Brake card upgrade kit (English pdf Brochure)ABB process control and automation solutions for Steep Incline Conveyors in Mine Processing Plant Belterra installed all the conveyor belts in this mines’ processing plant including the 4 HAC (high angle system) systems These vertical conveyors are specially designed for steep inclines requiring a minimal amount of space This system employs standard troughed belt components in a simple Mining Belterra• Added value through the integrated interaction of various plant components • Robust, lifetime design • Manufacturerindependence for components such as crushers, conveyor technology and peripheral machines such as maintenance cranes, dedusting systems, compressed air systems, hydraulic hammers and conveying systemsNiagara Mineral Processing Plant Haver Boecker This article first appeared in Mining Review Africa Issue 4, 2020 Read the full digimag here or subscribe to receive a print copy here Major or junior, Fraser Alexander offers bespoke processing solutions for all mining companies Throughput of its plants ranges from 50 to 700 tph and allows modular expansion when configured in parallel or in Process plant optimisation driven by Mining Review

Mining solutions ABB MineOptimize

Mining pilot project Retrofit of a 200 kW conveyor drive (English pdf Reference case study) 800xA control system for GMDs Protect all components of your grinding system (English pdf Reference case study) Plant Control System for ACC Limited, India (English pdf Reference case study) We provide you with versatile mineral processing, crushing and screening plants that can be reconfigured to any application and suit multiple layout options MAX Plant is an Australian own manufacture of mineral processing solutions for the aggregates, mining, construction and MAX Plant Crushing, screening mineral processing With professional SolidWorks 3D design software and PDM design management system, Xinhai can provide mobile mineral processing plant design; 3D mineral processing plant design; production line design of modular steel structure processing plant, that is, to design and manufacture the ore bin, water pond, platform, equipment support, hopper, chute and other reinforced concrete components into Mine Design, Mine Design Construction Plan Unused Crushing Plant Support Installations Purchased new for Uranium Heap Leach Mine Project Timed Online Auction January 28 February 4 2021 All components located in Dunkirk France Over €24 Million Eurodollar Purchase Cost Featuring Renault GIMAEX Fire Truck; All Terrain 8×8 Lube Truck; Two of (2) compressed air systems supporting Used Mining Processing Equipment Grinding Mills The current situation in most advanced mining operations is that some level of automation exists, be it in vehicles, ancillary machines, etc In mineral processing plants the level of automation is extensive ’s Chief Digital Officer, Jani Puroranta said in a 2019 article titled ‘Five levels of minerals processing plant autonomy’:The Resilience Mining Model AusIMM